Automation Lab

Project Videos

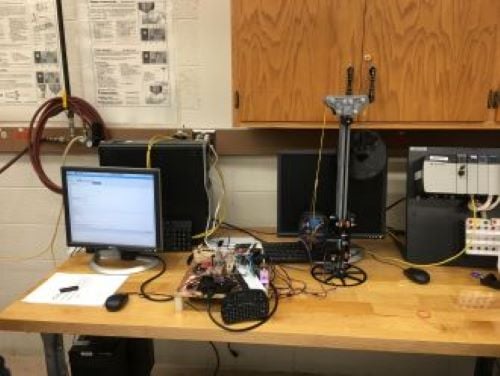

Every year students in MET 448 course use Arduino and Raspberry Pi to create solutions to unique industrial problems. Some of the videos of projects in the past years are shown here:

| Flexible Manufacturing Cell | Sorting of Metal Products in a product mix |

| Lego Pick and Place Project | 3D Printed Robotic ARM |

Lab Description

Next Generation Manufacturing Systems requires exploring concepts such as, smart manufacturing, Internet of Things (IoT), advanced robotics and automations in Reconfigurable and Flexible Manufacturing Systems (RMS/FMS) to achieve the factory of the future.

Next Generation Manufacturing Systems requires exploring concepts such as, smart manufacturing, Internet of Things (IoT), advanced robotics and automations in Reconfigurable and Flexible Manufacturing Systems (RMS/FMS) to achieve the factory of the future.

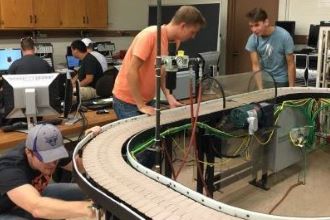

The Manufacturing Automation Laboratory is an 1800 square feet facility, designed to provide hands-on learning in the automation of manufacturing processes, as well as state-of-the-art education, research, and service in manufacturing system integration.

The lab has a variety of Rockwell Automation tools to provide hands-on experiences for students. Students utilize ladder logics for programming Programmable Logic Controllers (PLC) to automate and control equipment and devices. A number of PLC systems are designed and developed for automation controls, such as palletizing, pick and place, and product flow. The equipment includes an Automated Storage and Retrieval System (ASRS), Computer Numerical Control (CNC) lathes and milling machines for part creation and flow. The Flexible Manufacturing System from Amatrol is a scaled down industrial installation which is used for studying material flow, handing, fixturing, storage, retrieval, and production timing.

The lab has a variety of Rockwell Automation tools to provide hands-on experiences for students. Students utilize ladder logics for programming Programmable Logic Controllers (PLC) to automate and control equipment and devices. A number of PLC systems are designed and developed for automation controls, such as palletizing, pick and place, and product flow. The equipment includes an Automated Storage and Retrieval System (ASRS), Computer Numerical Control (CNC) lathes and milling machines for part creation and flow. The Flexible Manufacturing System from Amatrol is a scaled down industrial installation which is used for studying material flow, handing, fixturing, storage, retrieval, and production timing.

In addition to the manufacturing and control systems, the lab has a selection of anthropomorphic machines. Both articulated and Selective Compliance Articulated Robot Arm (SCARA) from Fanuc and Denso are utilized for course instruction and research.