High Performance Systems Lab

The High Performance Testing Lab houses engine and chassis testing equipment including 3 flow benches, camshaft measuring tools, engine measurement tools, a shock dynamometer, and an anti-roll bar test bench.

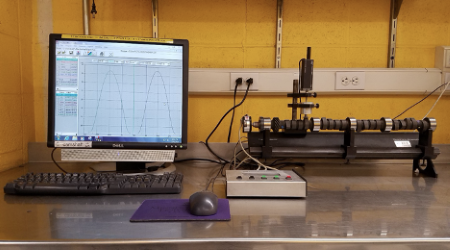

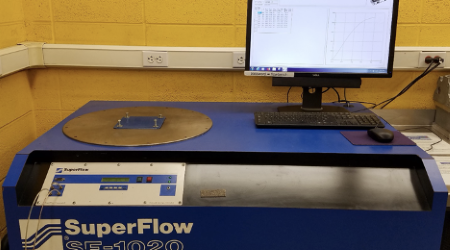

The High Performance Lab contains 3 flow benches each with a different flow range, which allows students to test air flow in a wide range of cylinder head sizes, or other air flow systems. Equipment in the lab allows student to test total port air flow at different valve lifts. Students also measure the flow characteristics at different locations in the port to get an idea of how the air is flowing and make decisions on how flow can be improved. Students are also able to measure camshafts to analyze intake and exhaust valve lift and timing. Combined with air flow measurements student can look at how air flows into the engine as the valves open and close. Students use this data to make design decisions both in class and on design projects. The use of measured airflow data is critical as airflow is crucial to engine operation.

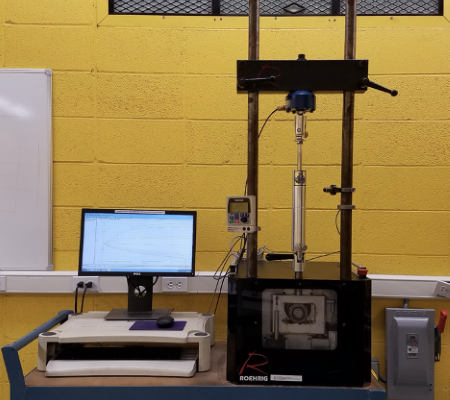

Also housed in the High Performance Lab is chassis testing equipment. The lab contains a shock dynamometer and test bench for testing anti-roll bars. Testing is essential to chassis performance. The shock dyno allows students to measure shock damping characteristics and make changes to damping curves to achieve desired performance goals. The dyno is capable of testing a wide range of shocks and allows students to compare shock performance at different valve settings and operating temperatures. Students also test anti-roll bar stiffness in the High Performance Lab and can use measured data to calculate the effects on vehicle load transfer based on a change in anti-roll bar stiffness.