Applied Research

Faculty in Manufacturing Engineering Technology program and students have a rich history of performing undergraduate research and presenting it locally, regionally and nationally.

Our students have conducted research in various fields such as additive manufacturing, automation, robotics, ergonomics and manufacturing processes.

Some of the conferences where our students have presented their work:

- Posters on the Hill, Washington, DC, 2014

- National Conference for Undergraduate Research, Ashville, NC, 2015

- SME NAMRC, Charlotte, NC, 2015

- Posters at St. Paul, St. Paul, MN, 2015

- Solid Freeform Fabrication Symposium, Austin, TX, 2017

- National Conference for Undergraduate Research, Memphis, TN, 2017

- National Conference for Undergraduate Research, Oklahoma City, OK, 2018

- Applied Ergonomics Conference, Atlanta, GA, 2018

- Applied Ergonomics Conference, New Orleans, LA, 2019

3D Printing (Additive Manufacturing)

The 750 Sq ft facility supports additive manufacturing and precision measurement course and laboratory work. Some of the equipment include 3D Printers based on Fused Deposition Modeling (FDM), Fused Filament Fabrication (FFF), Stereolithography (SLA) and Binder Jetting. Other equipment include a Coordinate Measurement Machine, Laser Scanner and Visual Dimensional Measurement System.

This lab is used for 3D printing projects in Intro to Parametric Modeling Class (MET 142), Quality Measurement in Metrology (MET 386) and Various Senior Design Projects. The lab is extensively used for undergraduate and graduate research projects. Students have presented this research in multiple national and international conferences. Research has also been published in peer reviewed Journals.

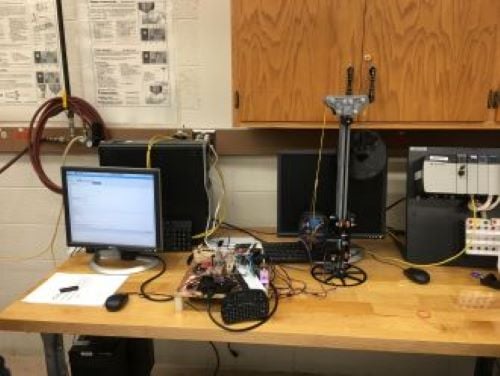

Automation and Robotics

Our department also has unique facilites for research in next generation robotics and automation technologies including IIoT, PLCs and Advanced Parametric Modeling. Students use Arduinos, Fanuc robotic arms and Advanced Creo tools to come up with unique solutions to challenging day to day problems.

Human Factors and Ergonomics

Dr. Shaheen Ahmed is a Certified Professional Ergonomist (CPE), who manages the Human Factors and Ergonomics Laboratory and Research in the Department of Automotive and Manufacturing Engineering Technology at Minnesota State University, Mankato. Students are trained on a wide variety of topics in human factors and ergonomics, including

- Physical ergonomics

- Cognitive ergonomics

- Organizational ergonomics

- Macroergonomics

- Sociotechnical system

- Psychosocial workplace ergonomics

- Work physiology applying heart rate data

- Workstation design applying anthropometric principles

- Screening tools and methods (e.g. RULA, REBA, JSI, SOFI, Borg, etc.) in the Human Factors and Ergonomics to evaluate, develop, and redesign products, manufacturing processes, service processes, office works, work environments, workplace, and work-tasks

- Manual material handling including the NIOSH lifting equations, and Snook Table

- Motion and time study