BS in Manufacturing Engineering Technology

College of Science, Engineering & Technology|Departments|Department of Automotive and Manufacturing Engineering Technology

College of Science, Engineering & Technology|Departments|Department of Automotive and Manufacturing Engineering Technology

Manufacturing involves plans, materials, personnel, and equipment which are transformed in some way that adds value. Students acquire leadership and managerial skills necessary to enter careers in process and systems design, manufacturing operations, maintenance, technical sales or service functions. The curriculum concentrates on the study of individual subsystems and their overall optimization of cost, quality, speed, and flexibility goals for the success of a manufacturing enterprise. Students from the program are currently employed in a wide variety of industries including medical, electronics, power systems, defense, and automotive.

Every year we graduate amazing students who go out and do wonders in industry and academia throughout Minnesota and the rest of the world. Here are their stories

|

Patrick LaQua Manufacturing Engineer Trystar, MN |

"I joined the AMET program for several reasons, here are a few. I've always been hands-on, always tinkering, trying to fix and build things. I came from a blue-collar background; a mechanic at one point, and a builder/fabricator at an off-road shop another. I loved the idea of enabling myself with the knowledge of an engineer. The hands-on realistic approach of the AMET program allowed me to utilize my previous years of experience while advancing my methodology. I now strive for solutions that not only make sense to an engineer, but also to the hard workers on the factory floors building products. I highly recommend the AMET program if you're like me and love the STEM field, but don't want to be stuck at a desk all day."

Our students make a difference when they graduate. Some of the areas they work in are

Most Manufacturing Engineering Technology Student Projects are industry based. Students work with industrial firms to solve real-world problems in a wide area of industrial concerns.

The BS in Manufacturing Engineering Technology coursework provides a broad technical background for students which enables graduates to take advantage of opportunities for advancement in many directions.

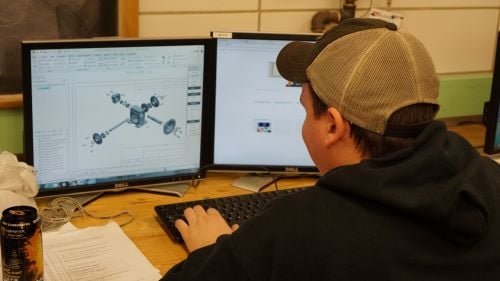

Workstations in CAD lab are equipped with Parametric Technology Corporation's (PTC) Creo ver. 2.0 parametric modeler with all its available modules. Currently, the PTC software is used for MET 142, MET 341, MET 386 and MET 347 courses and design projects. The lab maintains a limited number of licenses on Master CAM for teaching computer aided manufacturing (CAM).

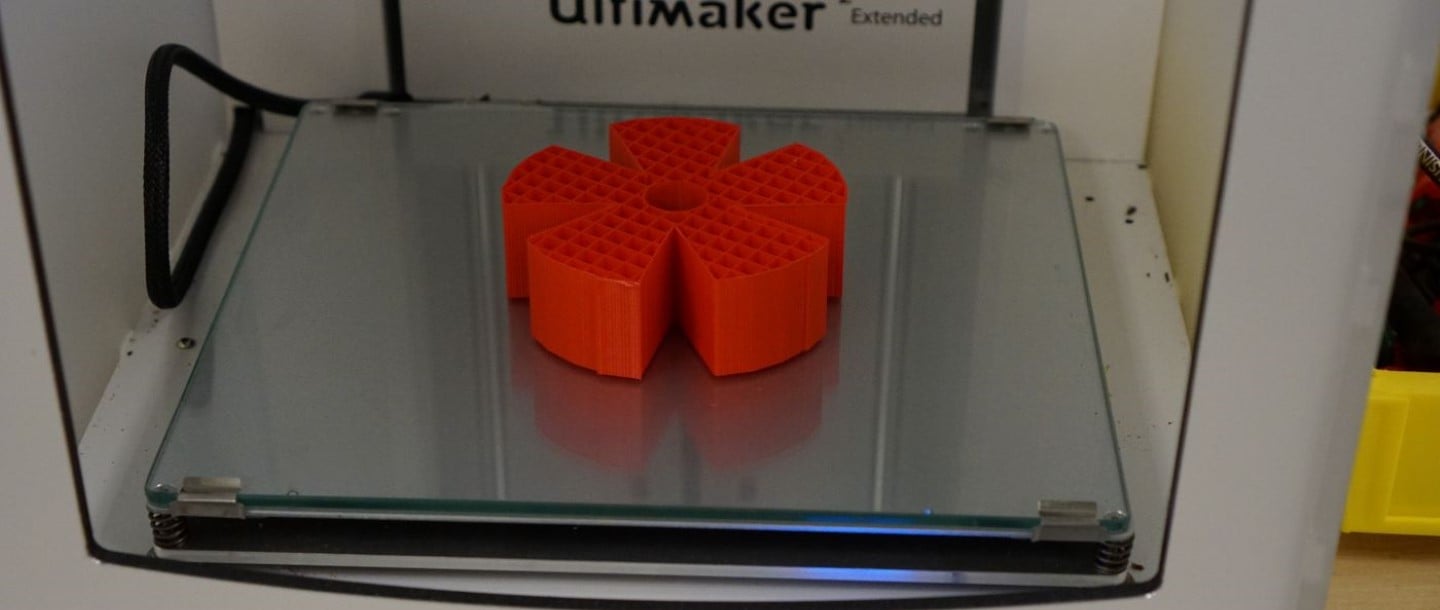

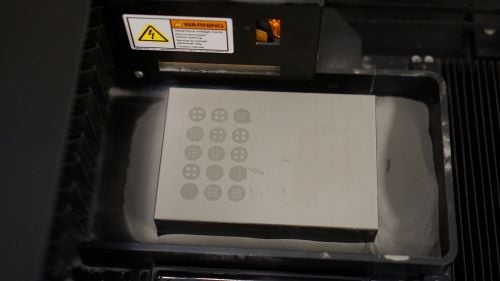

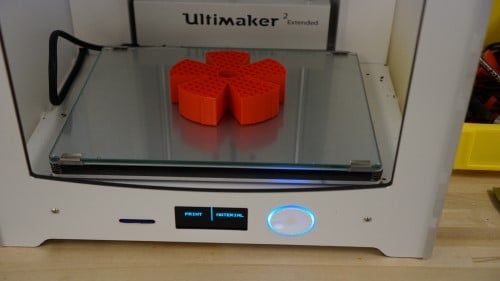

The 750 Sq ft facility supports additive manufacturing and precision measurement course and laboratory work. Some of the equipment include 3D Printers based on Fused Deposition Modeling (FDM), Fused Filament Fabrication (FFF), Stereolithography (SLA) and Binder Jetting. Other equipment include a Coordinate Measurement Machine, Laser Scanner and Visual Dimensional Measurement System.

The Manufacturing Engineering Technology program at Minnesota State University, Mankato is accredited by the Engineering Technology Accreditation Commission of ABET.

MET Program provides unique opportunities to students to pursue research during their undergraduate degree.

Students in MET Program can apply to multiple scholarships, on and off campus jobs and other positions to support their undergraduate program.

Although not required, internships are a valuable part of your education. Employers often hire the students they hire as interns. Students gain knowledge and experience necessary to begin their career.